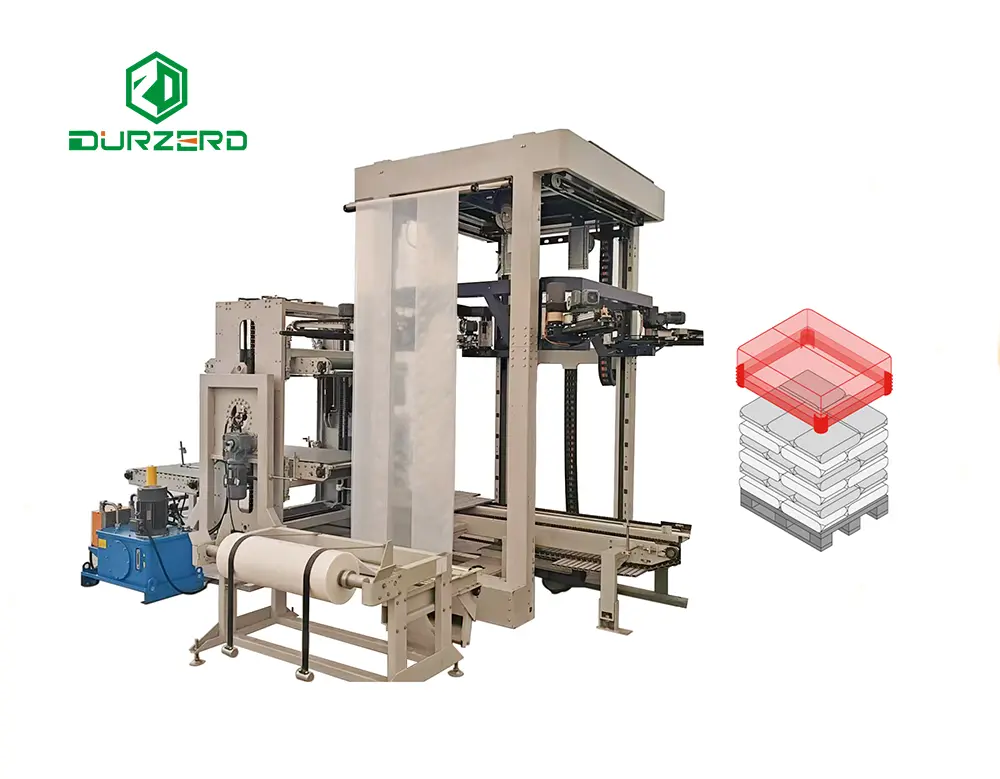

Product details of the automatic bag palletizer machine

Product Specification

Application: Food, Beverage, Commodity, Chemical, Machinery & Hardware

Product name: Automatic Stretch Hood Machine

Main Function: Stretch hood

Video outgoing-inspection: Provided

Weight (KG): 500

Quick Overview

The design of Durzerd automatic bag palletizer machine caters to the foreign markets. Before shipment, we will conduct various types of tests to check the quality of this product. Durzerd is very proud to produce such a popular automatic bag palletizer machine in the industry.

Product Information

automatic bag palletizer machine is more competitive than other products in the same category, as shown in the following aspects.

Efficient, Reliable, Robust, Streamlined

Our high speed stretch hooder equipment for pallets replaces traditional manual winding, providing more stability and improved productivity with quick and convenient operation. Using cold stretch film instead of ordinary packaging film saves costs for businesses, and the modular design of the equipment makes installation and assembly more convenient. The equipment is suitable for both Chinese and international standard pallets, with customizable stack heights, and ensures stable and reliable operation with user-friendly human-machine interaction.

Efficient and Versatile Pallet Wrapping

Superior load stability and protection

The high speed stretch hooder equipment for pallets offers superior load stability and protection, thanks to its advanced technology that ensures a tight, secure fit around the pallet.

Rapid operation and efficiency

Its rapid operation and efficient design save time and reduce labor costs, making it a cost-effective packaging solution for businesses.

Customizable features and user-friendly interface

With its customizable features and user-friendly interface, this equipment is a versatile and reliable choice for various industries.

Cost-effective packaging solution

The high speed stretch hooder equipment for pallets offers a cost-effective packaging solution for businesses, thanks to its efficient design and rapid operation.

Efficient, Reliable, Advanced Stretch Hooder

The High Speed Stretch Hooder Equipment for Pallets replaces traditional manual winding with stable, productive, and quick operation. It uses cold stretch film to save costs and ensures a small footprint with easy installation, thanks to its modular design. The equipment is suitable for both Chinese and international standard pallets, and features customizable stack heights and stable and reliable operation using Siemens-produced variable frequency drives, servo mechanisms and PLC. The equipment includes the following working process: Load Preparation, Film Placement, Stretching and Sealing, Cutting and Finishing.

Increase Warehouse Efficiency

The high-speed stretch hooder equipment is used to quickly and efficiently cover pallets with stretch film, reducing the time and effort required to secure goods for transportation.

Protecting Goods During Shipping

The equipment ensures that goods are securely wrapped and protected during shipping, reducing the risk of damage or loss in transit.

Trained personnel operate the equipment to ensure the safe and proper handling of pallets, preventing accidents and injuries in the workplace.

Distribution Center Operations

The equipment is commonly used in distribution centers to streamline the packaging and shipping process, improving overall efficiency and productivity.

The stretch hooder equipment is made of durable carbon steel spray, ensuring stability and longevity in operation. The film roll material is heat-sealable PE film, with a thickness of 120-150μm and a width of up to 1000mm. The applicable pallets for this equipment include those for bag, ton bag, carton, barrel, etc., and it is suitable for both Chinese and international standard pallets, with customizable stack heights.

1

What is a high-speed stretch hooder equipment for pallets?

A high-speed stretch hooder equipment for pallets is a machine designed to quickly and efficiently stretch a hood over a pallet, providing protection and stability to the goods on the pallet.

2

What are the main advantages of using high-speed stretch hooder equipment for pallets?

The main advantages of using high-speed stretch hooder equipment for pallets include increased efficiency, reduced labor costs, improved load stability, and enhanced protection against weather and damage.

3

What types of pallets can be used with high-speed stretch hooder equipment?

High-speed stretch hooder equipment is versatile and can be used with a wide range of pallet sizes and types, including wood, plastic, and metal pallets.

4

In what industries is high-speed stretch hooder equipment commonly used?

High-speed stretch hooder equipment is commonly used in industries such as food and beverage, pharmaceuticals, chemicals, and building materials, where palletized goods need to be protected during storage and transportation.

5

Can high-speed stretch hooder equipment be integrated into existing packaging lines?

Yes, high-speed stretch hooder equipment can be easily integrated into existing packaging lines, allowing for seamless and efficient pallet hooding without the need for major reconfiguration.

6

How does high-speed stretch hooder equipment contribute to sustainability in packaging?

High-speed stretch hooder equipment helps reduce material usage by optimizing film stretch and minimizing waste, contributing to sustainable packaging practices. Additionally, its efficiency can lead to reduced energy consumption and lower carbon emissions.

Company Advantages

Durzerd Packaging Machinery Co., Ltd. is a particularly famous automatic bag palletizer machine manufacturer. All Durzerd products are produced under the supervision of our quality control team and the quality of the products can be guaranteed. Durzerd Packaging Machinery Co., Ltd. is still working on to offer the distinguished automatic bag palletizer machine. Inquiry!

If you are interested in our products, please feel free to contact us.