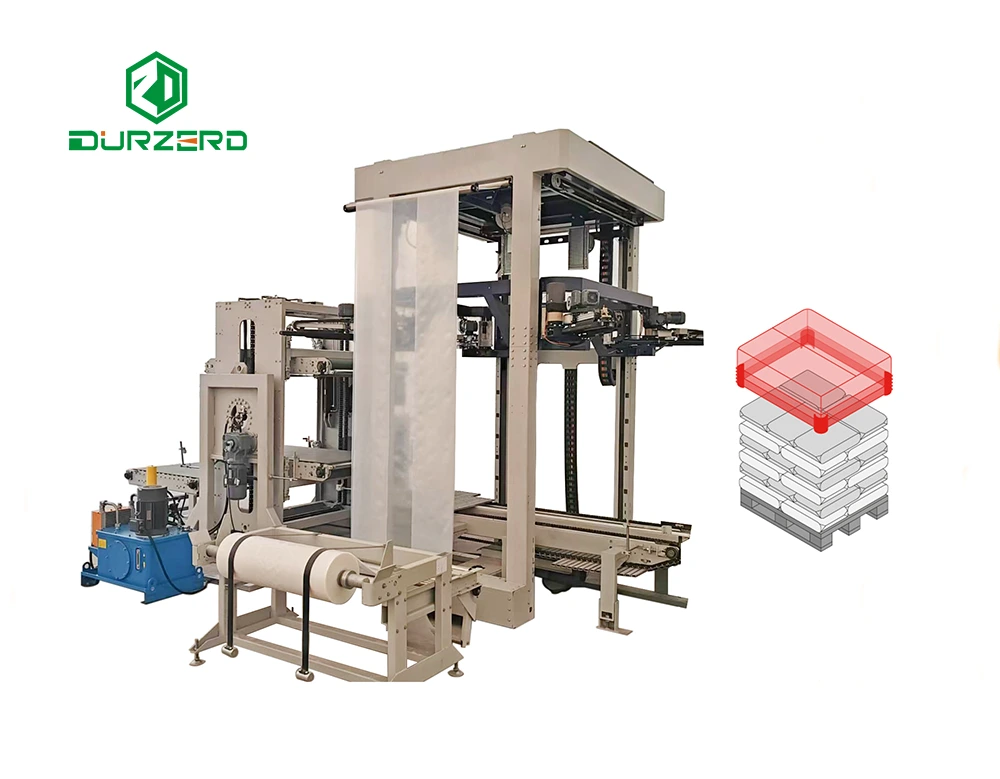

Pallet Stretch Hooding Machine - High-Speed Industrial Equipment

Efficient, Reliable, Robust, Streamlined

Our high speed stretch hooder equipment for pallets replaces traditional manual winding, providing more stability and improved productivity with quick and convenient operation. Using cold stretch film instead of ordinary packaging film saves costs for businesses, and the modular design of the equipment makes installation and assembly more convenient. The equipment is suitable for both Chinese and international standard pallets, with customizable stack heights, and ensures stable and reliable operation with user-friendly human-machine interaction.

Product Display

Efficient and Versatile Pallet Wrapping

Efficient, Reliable, Advanced Stretch Hooder

The High Speed Stretch Hooder Equipment for Pallets replaces traditional manual winding with stable, productive, and quick operation. It uses cold stretch film to save costs and ensures a small footprint with easy installation, thanks to its modular design. The equipment is suitable for both Chinese and international standard pallets, and features customizable stack heights and stable and reliable operation using Siemens-produced variable frequency drives, servo mechanisms and PLC. The equipment includes the following working process: Load Preparation, Film Placement, Stretching and Sealing, Cutting and Finishing.

Material Introduction

The stretch hooder equipment is made of durable carbon steel spray, ensuring stability and longevity in operation. The film roll material is heat-sealable PE film, with a thickness of 120-150μm and a width of up to 1000mm. The applicable pallets for this equipment include those for bag, ton bag, carton, barrel, etc., and it is suitable for both Chinese and international standard pallets, with customizable stack heights.

FAQ